CS-PT800 Sputtered Thin Film Pressure Transducer - CS-PT800

CS-PT800 Sputtered Thin Film Pressure Transducer - CS-PT800

Whole weld without O-ring

Excellent temperature stability

High over pressure and burst pressure

Customized pressure and electrical connection

Rugged housing

- Model Number: CS-PT800

- Data Sheet:

- category: Sensors| Pressure Sensors

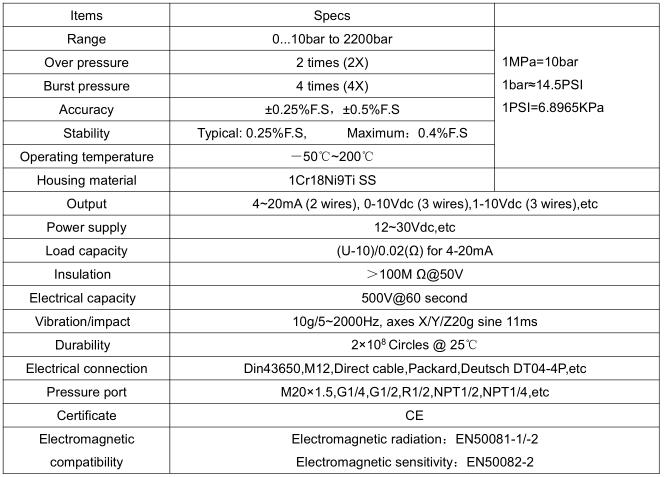

Product Specification

Sputtered Thin Film Pressure Transducer

Features

Whole weld without O-ring

Excellent temperature stability

High over pressure and burst pressure

Customized pressure and electrical connection

Rugged housing

Applications

Engineering machinery

High alpine environment

Natural gas storage equipment

Specifications

15x15 Respiratory Irritant Sensor 20 ppm P Package 110-901 - RESP_IRR_20 P

15x15 Respiratory Irritant Sensor 20 ppm P Package 110-901 - RESP_IRR_20 P

• Sensitive - In the ppb range

• Cold operation - No Heating required

• Small Size& Low Profile - 20x20x3 mm

• Easy to Use - Linear Response

• Long Life - 10 years expected life

• Fast Response - < 60 seconds

• ROHS Compliant

- Model Number: RESP_IRR_20 P

- Data Sheet:

- category: Sensors| Gas Sensors

Product Specification

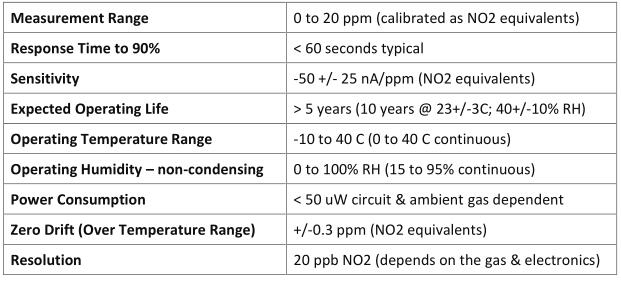

RESP_IRR_20 P Package 110-901

15x15 Respiratory Irritant Sensor 20 ppm P Package 110-901

DESCRIPTION

SPEC Sensors' RESP_IRR_20 is a Screen Printed ElectroChemical sensor component specifically designed for the broad detection of respiratory irritant gases: NO2, Ozone, Chlorines, SO2, H2S and odorous gases.

BENEFITS

• Zero Power Sensor

Sensor Circuit - < 10 uW max

• Sensitive - In the ppb range

• Cold operation - No Heating required

• Stable Response– Not affected by humidity, CO2, N2, Ar, most saturated hydrocarbons, hexane, ammonia,

• Small Size& Low Profile - 20x20x3 mm

• Easy to Use - Linear Response

• Long Life - 10 years expected life

• Fast Response - < 60 seconds

• ROHS Compliant

APPLICATIONS

• Bad Air Quality Detection

• Indoor Air Monitor

• Air Purifier Controls

• Weather Stations

• Internet of Things

• Smart Homes

• Leak Detection

• HVAC Ventilation Control

• Telemedicine Equipment

SPECIFICATIONS

Oxygen Sensor - O2-M2

Oxygen Sensor - O2-M2

O2-M2 Oxygen Sensor

parameter of oxygen sensor O2-M2:

1) Sensitivity <0.1

2) Output : 80 to 120uA @ 20.9% O2

3) Response time: < 15S from 20.9% to 0% O2

4) Zero current: < 2uA in N2

5) Linearity: 0.6 % O2 deviation @ 10% O2

6) Operating range > 24 months until 85% original output of 20.9% O2

- Model Number: O2-M2

- category: Sensors | Gas Sensors | Electrochemical Gas Sensors

Product Specification

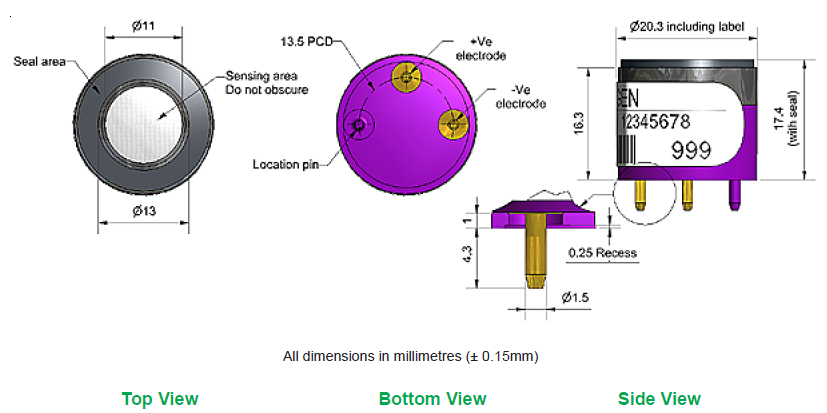

Figure 1 O2-M2 Schematic Diagram

PERFORMANCE

Output μA @ 20.9% O2 80 to 120

Response time t90 (s) from 20.9% to 0% O2 < 15

Zero current μA in N2 < 2.5

Linearity % O2 deviation @ 10% O2 0.6

LIFETIME

Output drift % change in output @ 3 months < 1

Operating life months until 85% original output of 20.9% O2 > 24

ENVIRONMENTAL

Humidity Sensitivity % O2 change: 0% to 95% rh @ 40°C < 0.7

CO2 sensitivity % (change O2 reading) / % CO2 @ 5% CO2 0.1

Pressure sensitivity (% change of output)/(% change of pressure) @ 20kPa < 0.1

KEY SPECIFICATIONS

Temperature range °C -30 to 55

Pressure range kPa 80 to 120

Humidity range % rh continuous (0 to 99% rh short term) 5 to 95

Storage period months @ 3 to 20°C (store in sealed pot, open circuit) 6

Load resistor Ω (recommended) 47 to 100

Diameter mm (including label) 20.0

Height mm (including foam ring) 17.4

Weight g < 16

4-Electrode Nitric Oxide Sensor - NO-B4

4-Electrode Nitric Oxide Sensor - NO-B4

4-Electrode Nitric Oxide Sensor

- Model Number: NO-B4

- Data Sheet:

- category: Sensors & Transmitters| Gas Sensor | Electrochemical Sensors

Product Specification

NO-B4 Nitric Oxide Sensor 4-Electrode

PERFORMANCE

Sensitivity nA/ppm at 2ppm NO 500 to 850

Response time t90 (s) from zero to 2ppm NO < 45

Zero current nA in zero air at 20℃ 30 to 140

Noise* ±2 standard deviations (ppb equivalent) 15

Range ppm NO limit of performance warranty 20

Linearity ppb error at full scale, linear at zero and 5ppm NO < ±1

Overgas limit maximum ppm for stable response to gas pulse 50

* Tested with Alphasense ISB low noise circuit

LIFETIME

Zero drift ppb equivalent change/year in lab air 0 to 50

Sensitivity drift % change/year in lab air, monthly test 0 to -20

Operating life months until 50% original signal (24 month warranted) > 24

ENVIRONMENTAL

Sensitivity @ -20℃ (% output @ -20℃/output @ 20℃) @ 2ppm NO 60 to 90

Sensitivity @ 40℃ (% output @ 50℃/output @ 20℃) @ 2ppm NO 97 to 110

Zero @ -20℃ nA 0 to 30

Zero @ 40℃ nA 100 to 200

CROSS SENSITIVITY

H2S sensitivity % measured gas @ 5ppm H2S (after 3 minutes) < 10

NO2 sensitivity % measured gas @ 5ppm NO2 (after 3 minutes) < 4

Cl2 sensitivity % measured gas @ 5ppm Cl2 < 3

SO2 sensitivity % measured gas @ 5ppm SO2 < 5

H2 sensitivity % measured gas @ 100ppm H2 < 0.1

CO sensitivity % measured gas @ 5ppm CO < 0.3

NH3 sensitivity % measured gas @ 5ppm NH3 < 0.1

CO2 sensitivity % measured gas @ 5% Vol CO2 < 0.1

O3 sensitivity % measured gas @ 100ppb O3 < 4

Halothane sensitivity @ 100ppm Halothane < 0.1

KEY SPECIFICATIONS

Bias voltage mV(working electrode potential is above reference electrode) +200

Temperature range ℃ -30 to 40

Pressure range kPa 80 to 120

Humidity range % rh continuous 15 to 85

Storage period months @ 3 to 20℃ (stored in sealed pot) 6

Load resistor Ω (ISB circuit is recommended) 33 to 100

Weight g < 13

O2-A2 Oxygen Sensor - O2-A2

O2-A2 Oxygen Sensor - O2-A2

Temperature range: -30 to 55 ℃

Pressure range :80 to 120 kPa

Humidity range:5 to 95 % rh non-condensing (0 to 99% rh short term)

Storage period :6 months @ 3 to 20℃ (store in sealed pot, open circuit)

Load resistor: 47 to 100Ω (recommended)

Diameter: 20.0 mm (including label)

Heigh: 17.4 mm (including foam ring)

Weight: < 16 g

- Model Number: O2-A2

- Data Sheet:

- category: Sensors | Gas Sensors | Electrochemical Gas Sensor

Product Specification

O2-A2 Oxygen Sensor

PERFORMANCE

Output μA @ 20.9% O2 80 to 120

Response time t90 (s) from 20.9% to 0% O2 < 15

Zero current μA in N2 < 2.5

Linearity % O2 deviation @ 10% O2 0.6

LIFETIME

Output drift % change in output @ 3 months < 1

Operating life months until 85% original output of 20.9% O2 > 24

ENVIRONMENTAL

Humidity Sensitivity % O2 change: 0% to 95% rh @ 40℃ < 0.7

CO sensitivity % (change O2 reading) / % CO2 @ 5% CO2 0.1

Pressure sensitivity (% change of output)/(% change of pressure) @ 20kPa < 0.1

KEY SPECIFICATIONS

Temperature range ℃ -30 to 55

Pressure range kPa 80 to 120

Humidity range % rh non-condensing (0 to 99% rh short term) 5 to 95

Storage period months @ 3 to 20℃ (store in sealed pot, open circuit) 6

Load resistor Ω (recommended) 47 to 100

Diameter mm (including label) 20.0

Height mm (including foam ring) 17.4

Weight g < 16

Object recognition to be launched at electronica 2016

Producer of custom designed, high performance Projected Capacitive Technology (PCT and MPCT) touch sensors, Zytronic, announced that, in collaboration with Tangible Display, it is able to offer object recognition capability on its MPCT multi-touch glass (ZyBrid) and foil (ZyFilm) sensor products up to 215cm in diagonal.

SICK announces TriSpector1000 Vision Sensor

SICK announces TriSpector1000, a stand-alone, configurable 3D vision sensor that reliably inspects objects regardless of variations in object color, shape, or position. In addition, intensity data enhances 3D navigation and allows the sensor to check for object rotation or the presence of a label or printed pattern.

The TriSpector1000 is especially suited for solving quality control applications in the consumer goods and packaging industry and can be used for volume and thickness measurement and inspection of box integrity, including content verification, completeness and emptiness checks. The TriSpector1000 also features IP 67 metal housing with plastic windows durable enough to withstand harsh food processing environments.

Find high quality sensor products, sensor manufacturers, sensor suppliers, sensor exporters on en.OFweek.com